-

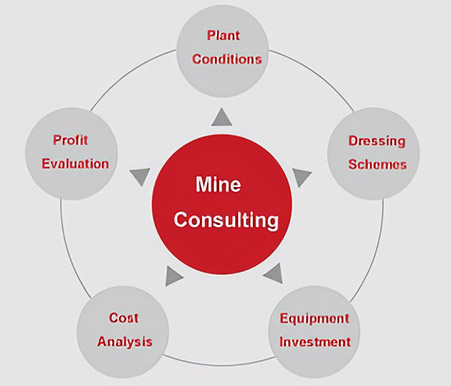

01. Purpose of Engineering ConsultingEngineering consulting makes clients have a comprehensive understanding of the value of mine, the useful elements, available mineral processing technology, plant size, required equipment and period.

01. Purpose of Engineering ConsultingEngineering consulting makes clients have a comprehensive understanding of the value of mine, the useful elements, available mineral processing technology, plant size, required equipment and period. -

02. Contents of Engineering ConsultingZhejiang Golden Support Department is responsible for engineering consulting. When a client needs engineering consulting, firstly, Zhejiang Golden Research Institute will arrange an expert with rich dressing experience to make sure whether can be separated according to the analysis of mineral elements. The basis of experts relying on in the mineral elements analysis mainly includes: elements content (number, type), elements distribution, recovery rate of useful elements etc.

02. Contents of Engineering ConsultingZhejiang Golden Support Department is responsible for engineering consulting. When a client needs engineering consulting, firstly, Zhejiang Golden Research Institute will arrange an expert with rich dressing experience to make sure whether can be separated according to the analysis of mineral elements. The basis of experts relying on in the mineral elements analysis mainly includes: elements content (number, type), elements distribution, recovery rate of useful elements etc.

After making sure the ore whether can be separated, Technology Support Department would contact with mineral dressing construction departments including geology, mining, ore dressing, smelting, machinery, civil engineering, electric power to get a brief quotation.

Zhejiang Golden mine consulting provides services according to the need of clients. The information clients providing is more detailed, the information of mines consulting is more detailed and accurate. The main contents of mines consulting include mining, mineral processing, external conditions, investment estimation and analysis of economic benefit. The engineering consulting illustrates all the problems in the construction olf dressing plant according to the limited information provided by the clients, so the experience of expert is a key. Only an expert with rich experience could provide detailed engineering consulting for the clients, which allows clients to have general understanding to their own mines and the value of dressing plant. -

03. Results of Engineering ConsultingAt last, engineering consult takes on economic benefits analysis for the customers including the cost analysis and profit estimate. Mine costs include mining, transportation, mining beneficiation, financial management cost. Profit estimate includes ore grade, product, price, annual output, total income, total cost, profit before tax, comprehensive estimation (time of recovering the investment).

03. Results of Engineering ConsultingAt last, engineering consult takes on economic benefits analysis for the customers including the cost analysis and profit estimate. Mine costs include mining, transportation, mining beneficiation, financial management cost. Profit estimate includes ore grade, product, price, annual output, total income, total cost, profit before tax, comprehensive estimation (time of recovering the investment).

Economic benefit analysis will allow clients to have a rough understanding about the investment and earnings of mine, and guide future investment.

-

In the feasibility study stage, first, Mine Design Institute and the client need to sign the entrustment agreement. work including: planning, investigation, data collection, planning and optimization, project evaluation, "report" writing, and exchanging views with commissioned units to form a formal report.

Design mainly involves dressing, general layout, electric power, communication, civil engineering, environmental protection, water supply and drainage, tailings, safety and fire protection, investment estimates, economic benefit. For the improvement and extension enterprises, the preliminary design will illustrate the status, characteristics, plant, main problems, utilization of main buildings and equipment.

When the working drawings completed, the designers must hand the drawings over to construction commanding officers, especially, the notes, strict regulation and important content.

-

In equipment manufacture, Zhejiang Golden takes advantages of a great deal of mining and ore dressing technicians to develop and improve 80% mining, dressing and smelting equipment by combining craft with machine manufacture. Some products reach the intemnational level with own characteristic. In the equipment processing, Zhejiang Golden production factory owns more than 100 sets of general machinery processing equipment for example vehicles, milling, planing, grinding, boring, drilling, punching, welding, bending, shearing and so on.

-

01.Nude PackingNude packing is mainly used for some equipments that is wear resistant, high quality, and without packing, such as the steel that install the material, shell plate of equipment, which saves cost for customers.

-

02.Bundle PackingBundle packing is suitable for angle steel, channel and steel pipe that used to install material, and the parts that with small size, large quantity and wear-resistant, such as stiffening plate, reinforcing plate and flange. Besides, it also demands shipping mark in the bundle packing equipment, indicating goods name, specification and quantity.

-

03.Rope Bundle PackingRope bundle packing is suitable for delicate and brittle equipment, such as bearing, belt conveyor, electric drum, etc.

-

04.Waterproof Winding PackingWaterproof winding packing is suitable for all loose packaged equipment, secondary machine and electrical products, reducer, electric control cabinet, it adopts stretch film packaging, which is waterproof, anti-corrosion and wear-resistant.

-

05.Snakeskin Bag, Airform Winding PackingThis packing method is mainly used for easily worn-off equipment that painted on surface which is rust-proof, wear-resistant and anti-collision.

-

06.Wood Pallet PackingSuitable for the goods with large quantity, easy to loosen and roll, such as blade of leaching tank, bracket of belt conveyor and carrier roller.

-

07.Wooden PackagingWooden packing applies to the equipment with large quantity and small size, such as spare parts, laboratory facilities and electrical material. Wooden packing should be attached to packing list, packing detail and DMAX.

For installation and commission, Zhejiang Golden upholds customer fist. There are 3 methods of installation and commission according to the actual situation of customers. -

08.Free guide of installationZhejiang Golden can send related veteran technician to guide customer with the equipment installation and commissioning for saving customer's cost. The customer should be responsible for the travel charge of the technician.

-

09.Contract for materialsZhejiang Golden arranges the installation and commission technicians, and clients prepare the components and instruments of installation of commission.

-

10.Contract for labor and materialsZhejiang Golden is responsible for tools, materials and personnel allocation of the installation and commission. Customers can directly wait for the final results.

-

Installation and commissioning is the key link for Zhejiang Gold to truly realize the beneficiation test, mine design, and equipment manufacturing in the overall service of the concentrator, and it is directly related to whether the concentrator can meet the standards and production.

On-site equipment installation and commissioning is a very meticulous and rigorous work with strong practicality. Any deviation may cause the recovery rate to drop and fail to reach the expected value. For example: the same type of equipment may have different opening positions in different constructions according to actual needs; installation deviations; subtle differences in water consumption and pharmaceutical usage in the beneficiation process, etc. These subtle differences will affect the final recovery rate. have a huge impact.

In view of the importance of on-site installation and debugging, Zhejiang Gold's equipment installation and debugging work is led by professional engineers and technicians responsible for installation and debugging. The installation and commissioning personnel sent by Zhejiang Gold for customers are selected from the old technicians who participated in the customer’s mine design throughout the process. This is mainly based on two considerations: First, the old technicians are experienced in the structure, performance and use of Zhejiang Gold’s self-produced equipment. Very familiar, can play a multiplier role in the installation and commissioning; second, because the technicians participate in the customer's mine design work throughout the process, the overall design of the customer's concentrator is well understood, and a large number of practical problems can be solved quickly in the construction of the concentrator.

Zhejiang Gold adheres to the principle of customer interests first. According to the actual situation of customers, it can provide 3 kinds of on-site installation and commissioning programs:

Free guide installation

All relevant majors send an experienced old technician to provide technical guidance on the installation and commissioning of the customer's plant selection equipment, saving customers the cost of installation and commissioning experts. The customer shall bear the travel expenses for the installation and commissioning of the guide abroad.

Work without materials

Zhejiang Gold is responsible for the deployment of personnel for the installation and commissioning of mineral processing equipment, and customers are responsible for the installation and commissioning of parts, tools and other materials.

All inclusive

Zhejiang Gold is responsible for all the tools, materials and personnel required for installation and commissioning, and the final acceptance by the customer.

-

01.

Operation TrainingOperation training for all workers involved in mineral processing.

Operation TrainingOperation training for all workers involved in mineral processing. -

02.

SolutionTraining for the common problems in the plant operation and processing technology; a live solution demonstration for workers.

SolutionTraining for the common problems in the plant operation and processing technology; a live solution demonstration for workers. -

03.

Operation ExperienceTraining of operation experience grasping, the workers should operate machines by lots of exercises.

Operation ExperienceTraining of operation experience grasping, the workers should operate machines by lots of exercises.

-

After the contract finished, Zhejiang Golden would regularly visit customer to provide after-sale technical support and to solve problems of dressing plant. For equipment of dressing plant, Zhejiang Golden could provide one-year warranty.

-

Gold Flotation ProcessFlotation is a method that is widely used in gold ore processing plant to process the rock gold ,commonly used in dealing with highly floatable sulfide minerals containing gold ore. Flotation process can enrich gold to the sulfide mineral , tailings can be abandoned directly , the cost of processing plant is low, 80% of China's rock gold are used in this method. Flotation process that mainly including dosing, mixing, filling, blowing foam etc.

Gold Flotation ProcessFlotation is a method that is widely used in gold ore processing plant to process the rock gold ,commonly used in dealing with highly floatable sulfide minerals containing gold ore. Flotation process can enrich gold to the sulfide mineral , tailings can be abandoned directly , the cost of processing plant is low, 80% of China's rock gold are used in this method. Flotation process that mainly including dosing, mixing, filling, blowing foam etc. -

Copper Beneficiation ProcessCopper ore divides into ore sulfide ,ore oxide and mixing ore according to its oxide rate. The main process for copper ore is flotation , for refractory mixed copper ore and refractory oxide ore , normally use hydrometallurgy process.

Copper Beneficiation ProcessCopper ore divides into ore sulfide ,ore oxide and mixing ore according to its oxide rate. The main process for copper ore is flotation , for refractory mixed copper ore and refractory oxide ore , normally use hydrometallurgy process. -

Scheelite Flotation ProcessScheelite dressing can use gravity, magnetic and flotation separation. The types and properties of the ore decide the separation methods and processes. Basing on good floatability of scheelite, the flotation is selected.

Scheelite Flotation ProcessScheelite dressing can use gravity, magnetic and flotation separation. The types and properties of the ore decide the separation methods and processes. Basing on good floatability of scheelite, the flotation is selected. -

Nickel Ore ProcessingNickel ore divides into copper sulfide and copper oxide ore , the main process for copper sulfide is flotation , magnetic and gravity separation is the subsidiary process .

Nickel Ore ProcessingNickel ore divides into copper sulfide and copper oxide ore , the main process for copper sulfide is flotation , magnetic and gravity separation is the subsidiary process . -

Chrome Ore ProcessGravity separation is the mainly process for chrome processing , sometimes the chrome concentrate will be separated by low intensity magnetic separation or high-intensity magnetic separation for a second processing , that's to improve the grade of the chrome .Several ores can use flotation or flocculation flotation process .

Chrome Ore ProcessGravity separation is the mainly process for chrome processing , sometimes the chrome concentrate will be separated by low intensity magnetic separation or high-intensity magnetic separation for a second processing , that's to improve the grade of the chrome .Several ores can use flotation or flocculation flotation process . -

PB-ZN Ore Dressing ProcessPB-ZN ore divides into sulfide Pb-Zn ore and oxide Pb-Zn ore . Flotation is the more widely used in separating sulfide Pb-Zn ore, to separate zinc and plumbum , sometimes for separating sulfide iron and other minerals . Sulfide Pb-Zn ore process dívides into priority flotation process , mix-separating flotation , asynchronous flotation ,and so on.

PB-ZN Ore Dressing ProcessPB-ZN ore divides into sulfide Pb-Zn ore and oxide Pb-Zn ore . Flotation is the more widely used in separating sulfide Pb-Zn ore, to separate zinc and plumbum , sometimes for separating sulfide iron and other minerals . Sulfide Pb-Zn ore process dívides into priority flotation process , mix-separating flotation , asynchronous flotation ,and so on. -

Phosphorus Ore Flotation ProcessAccording to different phosphorus ore property, phosphorus ore separating process have flotation, scrubbing desliming, gravity separation, chemical leaching, combined separating, photoelectric selection, magnetic coating, etc. the flotation is more applied, including direct flotation, reverse flotation, direct-reverse flotation and double reverse flotation.

Phosphorus Ore Flotation ProcessAccording to different phosphorus ore property, phosphorus ore separating process have flotation, scrubbing desliming, gravity separation, chemical leaching, combined separating, photoelectric selection, magnetic coating, etc. the flotation is more applied, including direct flotation, reverse flotation, direct-reverse flotation and double reverse flotation. -

Tailings Dry Discharge Process FlowsheetIn Current years, Tailings dry discharge is a gradual emerging new tailings treatment process. It means the tailing pulp from dressing plant through multi concentration, then use dewatering vibrating screen to treat and get low moisture, easy sediment solidify and good for stockpiling slag. Slag can be transport to fixed position for dry stockpiling.

Tailings Dry Discharge Process FlowsheetIn Current years, Tailings dry discharge is a gradual emerging new tailings treatment process. It means the tailing pulp from dressing plant through multi concentration, then use dewatering vibrating screen to treat and get low moisture, easy sediment solidify and good for stockpiling slag. Slag can be transport to fixed position for dry stockpiling.

EN

EN

English

English русский

русский 简体中文

简体中文