Machinery Factory

-

0+

0+Testing & producing equipments

-

0ton

0tonAnnual production

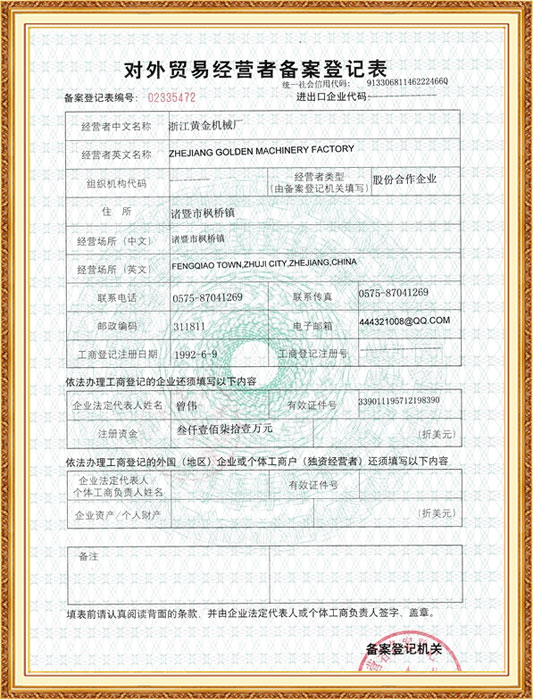

Zhejiang Golden Machinery Factory is China Mining Classifying Equipment Manufacturers and OEM Classifying Equipment Factory and also an advanced enterprise in Zhejiang province. There is a professional research and development center that integrates product R&D and manufacturing. The enterprise has about 200 various testing & producing equipments for the machinery manufacturing and with rich experience in installation and debugging work. Otherwise, the factory strictly implements of the IS09001: 2008 quality management system, and annual production of metal structures metal work are more than 25000 tons. We have stable technical cooperation with metallurgy, chemical industry academies. In tens of years developing, we gradually improve mixing enrichment equipments for hydrometallurgy. Currently, our technique and equipments of hydrometallurgy still at the domestic level. Because of the continuous innovation concept of leadership and the advanced technique, our enterprise has already become the enterprise in China that owned integrated technologies and equipments for hydrometallurgy.

The main products of the enterprise are crushing equipment and ball mill, mixing tank and flotation equipment, concentration and screening equipment, agitation equipment and large-scale mixing equipments for salt lake potash. It could provide complete sets of major technical equipments and complete sets of engineering for the mining, building materials, metallurgy, nonferrous metal, electric power, chemical industry, environmental protection and other basic industries. Domestically, it has already provided Western Mining, ZijinMining, Salt Lake Potash Fertilizer, Yuguang Gold and Lead, State-invested Potassium, Zhongiin Lingnan, Nafine, Jiangxi Coppe, Tongling Nonferrous Metals and other national key projects and listed enterprises with equipment and technology services. Besides, products are also sold to Asia, Africa, the United States, Australia and other countries and regions.

“Honesty, Innovation, High quality and efficiency, Users satisfied” is our business philosophy. We willing to provide our client with high-quality products and service. we will continue to work diligently, and hope cooperate with your sincerity, common development, and create the glorious future together!

-

Admin 23 Feb 2026

Which Mineral Grinding Equipment is Best for Your Plant: A Mill or a Grinder

Defining the Core Concepts: Milling vs. Grinding In the realm of industrial material processing, the terms "milling" and "grinding" are frequently used as synonyms. However, for engineers and plant managers seeking to optimize a production line, the distinction is vital. Milling ...Read More

-

Admin 16 Feb 2026

Which Mineral Grinding Equipment offers the best energy efficiency for hard rock processing

The Critical Role of Mineral Grinding Equipment in Modern Mining In the complete flow of mineral processing, Mineral Grinding Equipment holds a core position following the crushing stage and preceding the concentration stage. Comminution operations typically account for more tha...Read More

-

Admin 09 Feb 2026

What are the different types of mining mixing tanks and how to choose the right one

Main Types and Working Principles of Mining Mixing Tank In practical mining applications, the selection of a Mining Mixing Tank depends on pulp viscosity, particle settling velocity, and process requirements for mixing intensity. Below are the detailed analyses and technical para...Read More

What is the basic working principle of mineral classifying equipment?

Mineral classifying equipment is a vital part of the mineral processing process. Its main function is to classify and grade the ore according to the physical properties of the mineral particles (such as particle size, density, etc.). This process helps the subsequent beneficiation and smelting operations, optimizes the utilization of resources, reduces unnecessary energy consumption, and improves the overall ore processing efficiency.

Basic working principle of mineral classification

The basic working principle of mineral classification is to use the movement characteristics of different mineral particles in the medium (usually water) to classify the particles in the ore into different levels. According to the characteristics of different mineral particles, the following main classification methods can be used:

Gravity classification method: This is based on the density difference of different mineral particles to achieve classification. The ore settles in the water, and the heavier minerals will settle quickly, while the lighter ones will be retained in the water flow. This principle is mainly used in hydraulic classifying equipment, such as cyclones and settling tanks.

Screening classification method: Screening classification is achieved by limiting the aperture of the screen or grid. The ore is fed into the screening machine, and the larger particles cannot pass through the sieve holes and are left behind, while the smaller particles pass through the screen, thereby separating the ore particles.

Airflow classification method: Airflow classification classifies particles by particle size through airflow. Lighter particles will float with the airflow, while heavier particles will settle down. This method is mostly used for the classification of fine minerals.

Centrifugal classification method: Centrifugal force is used to separate ore particles. Heavier particles are thrown to the outside under the action of centrifugal force, while lighter particles are pushed to the center. Centrifugal classifiers are often used to process minerals with large differences in particle density.

The selection and design of mineral classifying equipment needs to be determined based on factors such as the physical and chemical properties of the ore, the mineral composition, and the particle size distribution of the ore. Reasonable equipment selection can effectively improve the ore sorting efficiency, reduce energy consumption, and optimize the mineral processing process.

Zhejiang Golden Machinery Factory's technical advantages

As one of China's leading mineral classifying equipment manufacturers, Zhejiang Golden Machinery Factory (the former Zhuji Nonferrous Metallurgical Machinery Complex Factory) has been committed to providing efficient and reliable mineral classifying equipment for the global mining, metallurgy, chemical and other industries with advanced technology and rich experience.

As an enterprise with many years of development history, Zhejiang Golden Machinery Factory not only has first-class R&D and manufacturing capabilities, but also strictly produces in accordance with the ISO9001:2008 quality management system to ensure that each equipment meets international standards. In the field of mineral classification, the cyclones, vibrating screens, screening machines and other equipment provided by Zhejiang Golden Machinery Factory have been widely used in mining companies at home and abroad.

1. Cyclone

As an important part of hydraulic classifying equipment, the cyclone adopts the centrifugal classification principle and can effectively classify the ore. The cyclones produced by Zhejiang Golden Machinery Factory have the characteristics of sophisticated design, high classification efficiency and stable operation, and can handle minerals with a wide range of particle sizes. In many large-scale mining projects at home and abroad, cyclones have become key equipment for improving ore recovery and optimizing production processes.

2. Vibrating screen and screening machine

Zhejiang Golden Machinery Factory's vibrating screen uses advanced vibration technology, which can effectively screen fine particles in the ore and optimize the particle size distribution of the ore. The design of the screen not only improves the passing efficiency of the mineral, but also extends the service life of the equipment. In addition, the screening machine in the factory can provide a variety of screen aperture options according to the different properties of the minerals to ensure more accurate ore sorting.

3. Precision classification technology

Zhejiang Golden Machinery Factory continues to promote the research and development of precision classification technology through cooperation with many scientific research institutions at home and abroad. Especially when dealing with complex ores and fine-grained minerals, the mineral classifying equipment in the factory can provide higher classification accuracy, significantly reduce the loss of fine particles, and improve the ore recovery rate.

How to choose appropriate classifying equipment according to the particle size of the mineral

Classification and grading in the mineral processing process are very critical steps, which can ensure the further processing effect of the mineral, improve the efficiency of mineral processing, and avoid resource waste. Mineral particles of different particle sizes have different physical properties and behaviors, so it is crucial to choose the right mineral classifying equipment.

Basic principles of mineral classification

The working principle of mineral classifying equipment is usually based on the physical differences of ore particles, such as particle size, density and shape. For the classification of mineral particle size, the following common classification methods are generally used:

Screening method: Separate mineral particles of different particle sizes by screening with a screen or mesh aperture. Larger particles are blocked on the screen surface, while smaller particles can pass through the screen.

Hydraulic classification method: Classify by using the difference in the sedimentation rate of mineral particles in water. Larger particles will settle quickly due to gravity, while fine particles will be suspended in the water flow.

Airflow classification method: Classify particles by particle size through airflow, lighter particles float with the airflow, and heavier particles are pushed in the other direction.

Centrifugal classification method: Based on the distribution characteristics of particles under the action of centrifugal force, heavier particles are thrown to the outside, while lighter particles are concentrated in the center.

Select classifying equipment according to mineral particle size

Mineral particles of different particle sizes are suitable for different types of mineral classifying equipment. Particle size directly affects the selection and design of classifying equipment. The following are several common ways to match particle size ranges with classifying equipment:

Coarse-grained minerals (>10 mm):

For larger-grained minerals, vibrating screens and gravity classifying equipment are usually used. Vibrating screens can effectively separate larger-grained minerals. Due to the aperture limit of the screen, larger particles cannot pass through the screen, while fine particles can pass smoothly. In addition, gravity classifying equipment (such as settling tanks and cyclones) can also play a role in the treatment of coarse-grained minerals. Gravity classification separates larger particles through the sedimentation characteristics of mineral particles in water.

Medium-grained minerals (1 mm~10 mm):

For medium-grained minerals, spiral classifiers and cyclones are common classifying equipment. Spiral classifiers use the spiral motion of spiral blades to separate ore particles according to density and particle size. The cyclone generates centrifugal force through rotation, and larger particles settle to the bottom of the equipment faster, while smaller particles float in the water flow, thereby achieving particle classification.

Fine-grained minerals (<1 mm):

The classification of fine-grained minerals is usually more complicated, and traditional screening and hydraulic classification methods may not be effective. In this case, airflow classifiers and high-efficiency cyclones are more suitable for processing fine-grained ores. Airflow classifiers classify fine particles through high-speed airflow, and can accurately separate mineral particles of different sizes. High-efficiency cyclones can provide higher classification accuracy in the processing of fine particles, minimizing the loss of fine particles.

How does the screening efficiency of mineral classifying equipment affect the processing efficiency of ore

In the ore processing process, mineral screening is a crucial link, which directly affects the subsequent processing effect of the ore, the mineral processing recovery rate and the overall production cost. The level of screening efficiency not only determines the separation quality of ore particles, but also greatly affects the efficiency of the entire ore processing process.

Relationship between screening efficiency and ore processing efficiency

The screening process is essentially to classify ore by particle size through a physical screen or other sorting media. This process is crucial for the fine processing of ore. Screening efficiency refers to the ability of screening equipment to separate ore by particle size per unit time, which directly affects the sorting accuracy and processing speed of the ore. If the screening efficiency is low, it will lead to incomplete sorting, particle mixing, and may even affect subsequent flotation, gravity separation and other processes, thereby reducing the final recovery rate of the ore.

Particle size control and screening efficiency

The screening efficiency is directly related to the particle size distribution of ore particles. When the efficiency of the screening equipment is high, ore particles of different particle sizes can be separated more accurately, providing an ideal particle size range for subsequent processes (such as flotation, gravity separation, etc.). If the screening effect is not good, it may cause too many fine particles or coarse particles to mix with minerals that should not be processed, thereby affecting the fine processing effect of the ore.

Improve productivity

In mining production, screening efficiency directly affects the processing capacity of ore. Higher screening efficiency means that more ore can be processed per unit time, thereby improving overall productivity. For example, the high-efficiency vibrating screen equipment produced by Zhejiang Golden Machinery Factory can greatly improve the screening efficiency of ore. By optimizing the design of vibration frequency and screen aperture, the processing capacity is significantly improved. The application of this technology not only improves the screening accuracy of ore, but also speeds up the production process.

Improve the recovery rate of ore dressing

The improvement of screening efficiency helps to sort out higher quality minerals during the ore dressing process, avoid unnecessary ore loss, and maximize the recovery rate of ore. In the mineral processing process, the screening link is the first step to determine the ore sorting effect. Therefore, the screening efficiency directly affects the recovery effect of the ore. The screening equipment developed by Zhejiang Golden Machinery Factory can effectively improve the screening efficiency after years of technical optimization, thereby ensuring that more high-quality minerals are sorted out and improving the recovery rate.

Reduce energy consumption and cost

Optimizing screening efficiency helps to reduce energy consumption and operating costs. If the screening equipment is inefficient, it takes longer and more energy to process, which increases production costs. Zhejiang Golden Machinery Factory's vibrating screens and high-efficiency cyclones and other equipment use advanced vibration technology and structural design to make the screening process more efficient, reduce energy waste, and reduce equipment operation and maintenance costs and energy consumption, thereby saving customers a lot of operating costs.

EN

EN

English

English русский

русский 简体中文

简体中文